Images

Using advanced automation and technology to power industries.

Our machines stand as a testament to precision engineering and unmatched efficiency, delivering performance that drives progress and innovation.

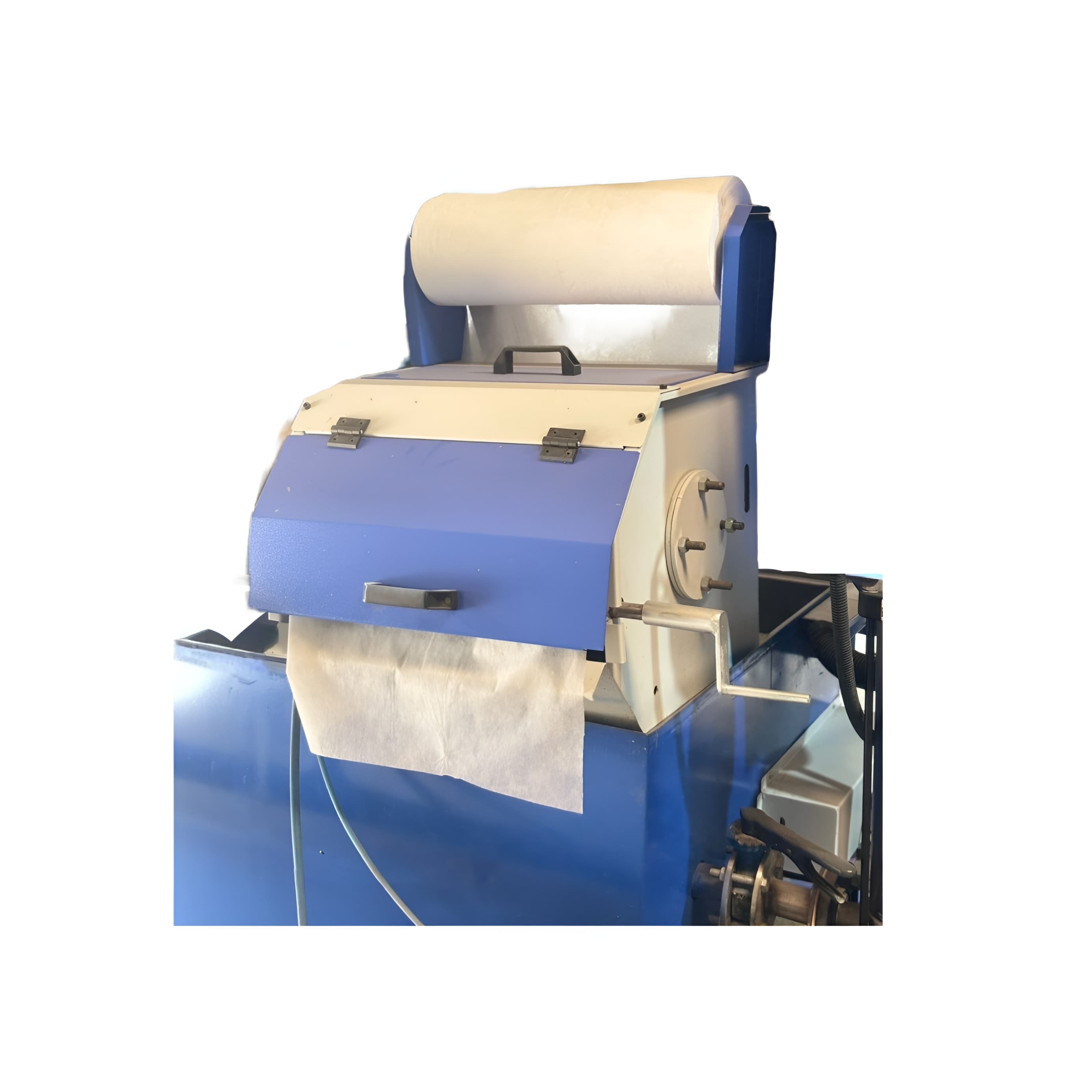

High Pressure,Bin/Component Cleaning Machine.Compact Band Pape

Standard 800 dia rotary basket,20 bar capacity pump,compact band paper filtration system,PlC control,weight carring capacity 60 to 80 kgs,600MM × 400MM × 300MM height capacity maxs,water tank capacity 300 to 350 LTRS, oil skimmer,water level indicator and maintenance friendly machine.

Ultrasonic Cleaning Machine.

Ultrasonic Cleaning is the preferred high-precision cleaning technique that is designed to remove surface contamination from products completely and rapidly.The ultrasonic cleaning process design depends on factors like the component or product type, material, surface quality, contamination type and required cleanliness level.(e.g, particle size and Millipore values)

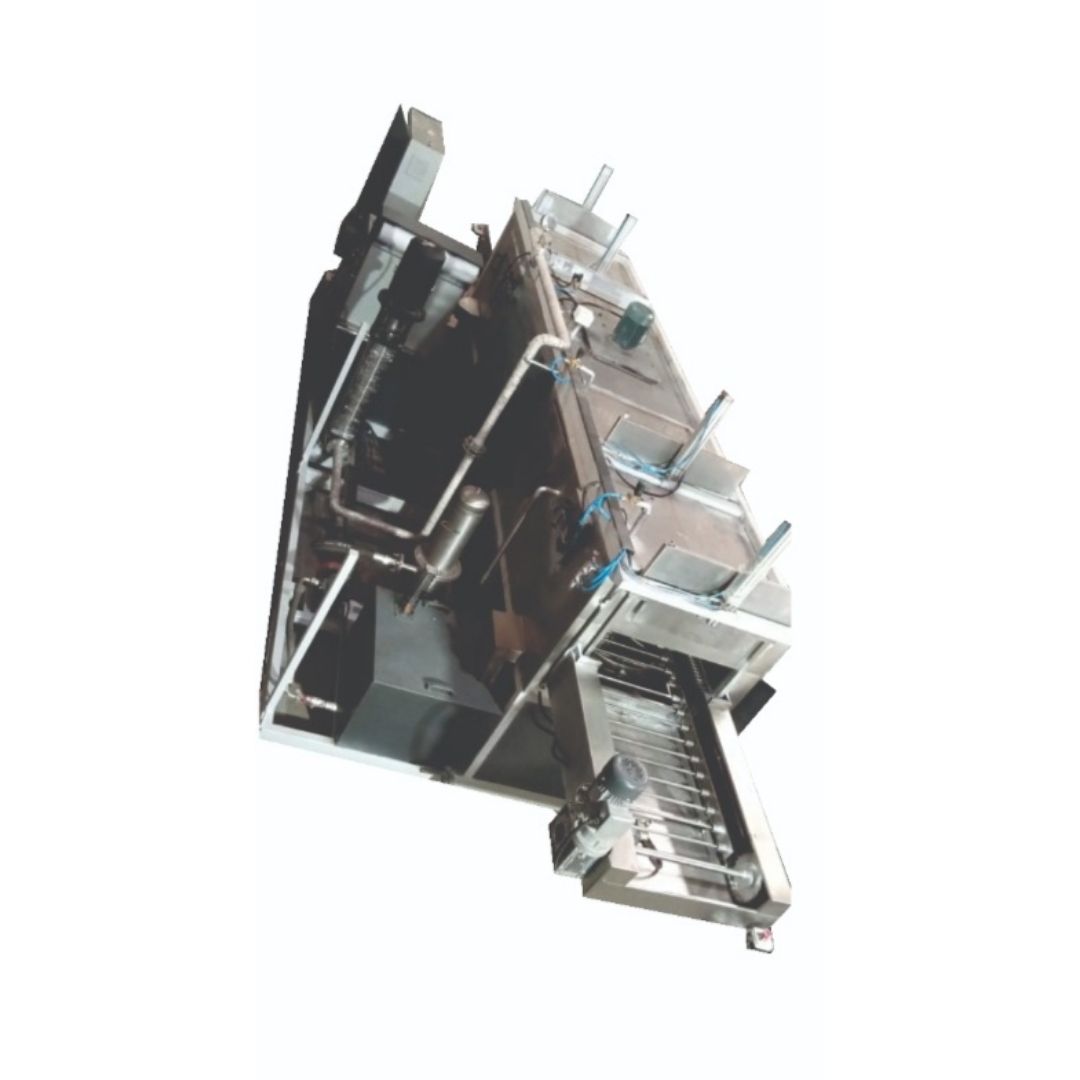

Multi Stage Equal Indexing Converised Component Cleaning Machine.

High pressure rotary cleaning, ultrasonic cleaning, air cartan for drying,oven/hot air blow for drying,retutn line conveyor for basket,PLC control, millipore upto 1 to 2 micron and maintenance friendly machine.

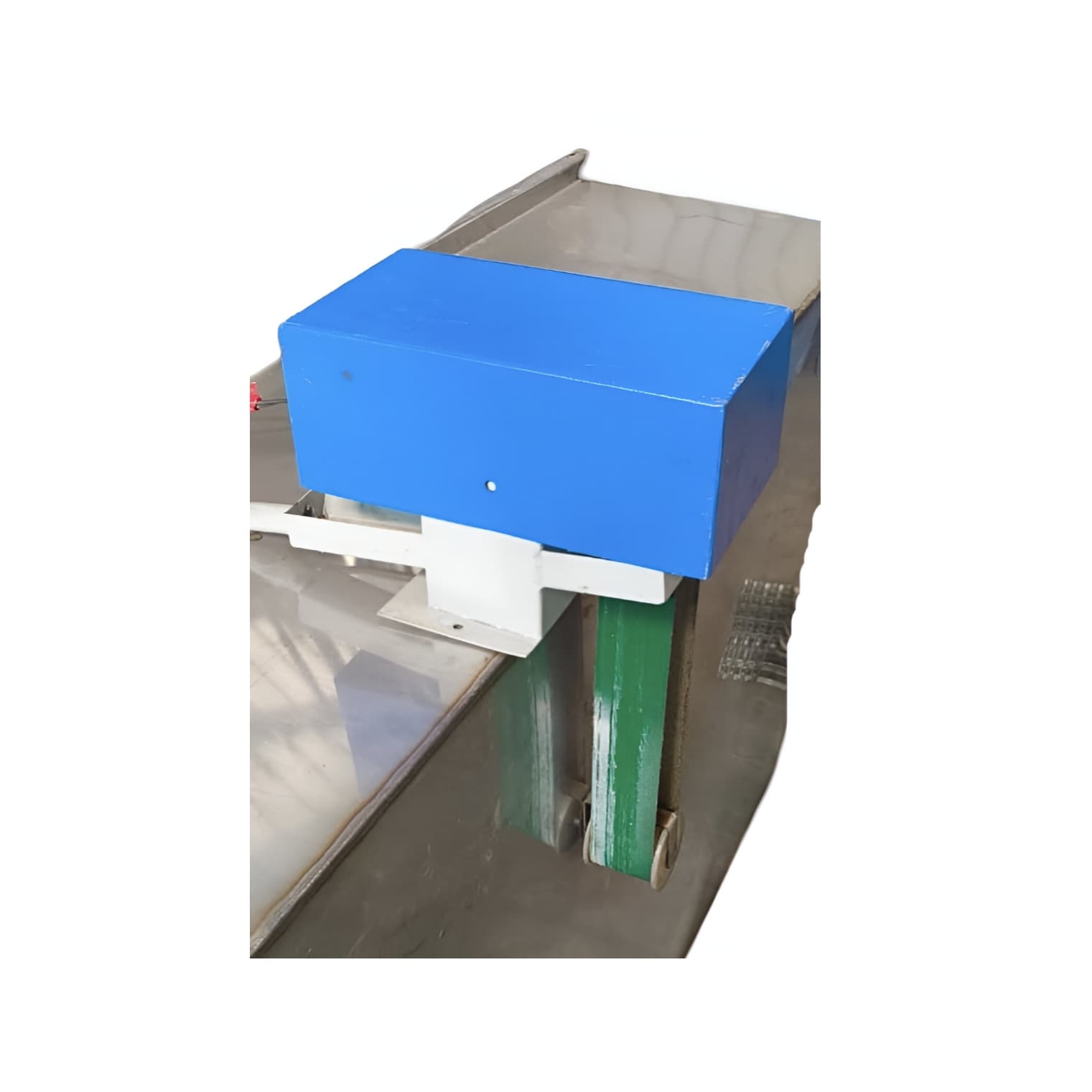

Compact Band Filtration.

Compact design to remove impurities from coolant.Levet type limit switch.Fully automatic operation float switch sensor to remove clogged filter paper automatically.Availagble in standard models.Customized design to suit specific requirements.Also made available.Filtration: 15,25,50 Microns.Moc. MS, SS 30H.Magnetic Seperator add - on available.Skimmer add-on avilable.

Oil Separator.

To separate Tramp Oil from CNC Machines,No filter element,No replacement cost.Improved product finish,Extended Oil change period.Reduced machine downtime,Substantial saving on Mfg and Maintenance Expenses.

Oil Skimmer.

To separate floting Oil from water and maintenance friendly unit.